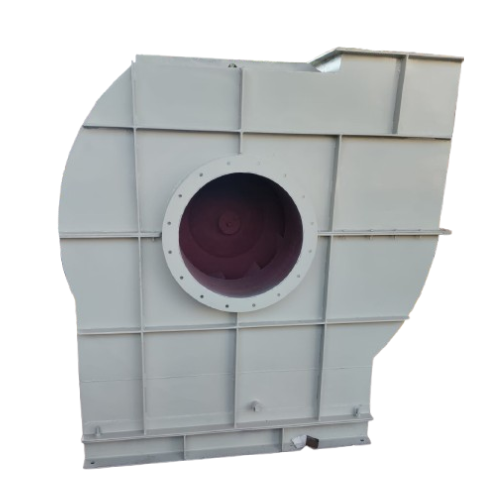

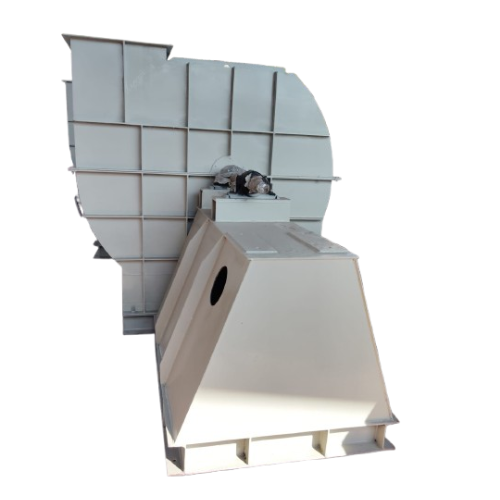

FD Fan

FD Fan Specification

- Air Flow

- Up to 40000 CFM

- Instruments Type

- Industrial Fan

- Usage & Applications

- Boiler Air Supply, Industrial Ventilation

- Orientation

- Horizontal

- Measurement

- Manual

- Power Source

- Electric

- Temperature

- Up to 80C

- Automation Grade

- Semi-automatic

- Efficiency

- Up to 85%

- Product Type

- FD Fan

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- 75 dB

- Processing Time

- Continuous

- Capacity

- 5000 - 40000 CFM

- Voltage

- 415 V

- Weight

- Approx. 250 kg

- Dimension (L*W*H)

- 1800 x 1200 x 1300 mm

- Surface

- Powder Coated

FD Fan Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- EX-WORKS, FOR

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About FD Fan

This heavy duty FD fan is used as integral part of steam/coal fired/CFB boilers. Made of Q235/Q235 grade steel, this fan can be operated at 10 degree C to 200 degree C temperature range. Driven by 3 phase motor of imported quality, this energy efficient fan deserves praise for its excellent air delivery, high speed rotation and low noise operation. As part of its mechanism, forced draft fan ( FD) supplies required air to the air pre-heater system. This pre-heater collects or captures heat discharged by the outlet of boiler. Offered FD Fan is quick to install and is simple to maintain.

Product details

|

Material |

MS |

|

Air Volume |

15000 CMH |

|

Pressure |

500 mmWG |

|

Voltage |

415 |

|

Impeller Size |

36 inches |

|

Type |

Forced Draft Fan |

|

Fan Speed |

1480 |

|

Power |

40 HP |

Engineered for Industrial Performance

Designed specifically for tough industrial conditions, the FD Fan features a backward curved impeller and floor/base mounting for stability. Its powerful and energy-efficient motor supports continuous operations, making it a preferred choice in cement, steel, textile, and power generation industries.

Optimal Airflow and Efficiency

The FD Fan delivers up to 40,000 CFM, ensuring effective boiler air supply and industrial ventilation. With efficiencies up to 85% and eight to sixteen blades, it achieves high-volume air movement while maintaining a manageable noise level of 75 dB.

Durability with Low Maintenance

Constructed from premium-grade mild steel and finished with a powder-coated surface, the FD Fan is built to last. It requires minimal maintenance, offering a long operational lifespan and reliable service under continuous use.

FAQ's of FD Fan:

Q: How does the backward curved impeller improve the FD Fan's performance?

A: A backward curved impeller enhances efficiency by reducing air turbulence and increasing energy conversion, allowing the fan to deliver high airflow (up to 40,000 CFM) at lower power consumption, supporting prolonged industrial use.Q: What industries benefit most from this FD Fan model?

A: This fan is ideal for cement, steel, textile, and power generation industries, where continuous, high-capacity air movement and reliable boiler air supply are critical for operational efficiency and equipment protection.Q: When is it recommended to use a floor/base mounted, belt-driven FD Fan?

A: A floor or base-mounted, belt-driven configuration is best suited for environments requiring stable installation, adjustable speed, and ease of maintenance-especially important in demanding industrial applications with continuous operation.Q: Where should the FD Fan be installed for optimal operation?

A: Install the FD Fan in well-ventilated industrial spaces near boiler rooms, production halls, or areas needing efficient air supply and exhaust, ensuring clear airflow paths and easy access for periodic inspection and maintenance.Q: What makes the FD Fan suitable for high-temperature applications?

A: The FD Fan is air cooled and built from mild steel with a powder-coated surface, allowing safe and efficient operation in environments with air temperatures up to 80C without performance loss or material degradation.Q: How does the belt drive arrangement benefit the maintenance process?

A: The belt-driven system allows for easier replacement of worn belts and precise speed adjustments. This reduces downtime, simplifies maintenance, and ensures reliable fan operation over its long service life.Q: What are the key benefits of using this FD Fan for boiler air supply and industrial ventilation?

A: Key benefits include high airflow efficiency, low maintenance requirements, robust construction, long service life, and flexible application in various industrial settings, supporting improved air quality and equipment efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Pollution Control Equipment Category

Centrifugal Fan

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Centrifugal Fan

Material : Mild Steel

Weight : 350 kg

Usage & Applications : Industrial Ventilation, Air Pollution Control, HVAC Systems

Pulse Jet Bag Filter

Price 115500.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Pulse Jet Bag Filter

Material : Mild Steel

Weight : 2500 8000 kg

Usage & Applications : Industrial

Cartridge Filter

Price 1150 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : Cartridge Filter

Material : Polypropylene (PP), Stainless Steel

Weight : 8 Kg

Usage & Applications : Water Treatment, Industrial Filtration, Chemical Processing, Food & Beverage, Pharmaceutical

Homopolymer Acrylic Filter Bags

Price 700.0 INR / Bag

Minimum Order Quantity : 100 Pieces

Product Type : Filter Bag

Material : Homoploymer Acrylic Fabric

Weight : Varies by size and design

Usage & Applications : Industrial dust collection, chemical industries, hightemperature filtration, pharmaceutical and food processing